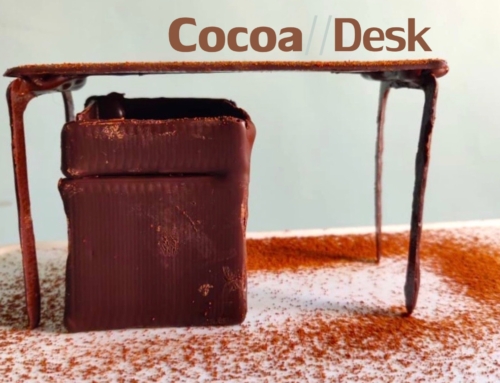

No, your eyes and brain are not deceiving you. Yes, you read that right – 3D Printed. Food. In this article we are going to dive into the Origins of 3D printed food.

There are more advancements than ever before in this niche field – from food companies and patisseries, to healthcare and even in space exploration! Could 3D printing change the way we cook and eat?

Since the 1980s, steady progress has been made in 3D printing materials, from thermoplastics to metals, and now even food!

So how does a 3D food printer work? We asked Jashan Sippy, a food-architect and 3D food printing expert to share his views.

“3D food printing works just like a printing filament with a regular 3D printer: a viscous material is deposited onto a surface to create a final object.”

Sounds pretty simple, right?

There have been several studies with other additive manufacturing processes like binder jetting, laser sintering with powdered foodstuff, but it’s still debatable whether these processes are viable for printing food at scale or not.

A brief history of 3D printed food

In 1984, Chuck Hull invented the process of stereolithography but it wasn’t until 1986 that he patented the first stereolithography printer and the .STL file format (which is what we use even today). In 1988, Stratases and 3D systems together developed their first 3D printers but it wasn’t until 1996 that the word 3D printing was starting to be used for the first time.

Then in 2004, we first started printing food. “So 3D food printing is just about 20 years old”, Jashan explains.

And it wasn’t until 2010 that the first personal 3D printer was sold. So in reality 3D printed food is still in its infancy, and it has a really long way to go before we can start seeing it being broadly adopted by professionals as well as consumers. However this doesn’t stop us from marvelling at all the fascinating machines and the intriguing edible designs that are possible to create using this emerging technology.

About Jashan Sippy:

Jashan is a green-building certified architect specialised in the design for spaces for food. He is the founder of Sugar and Space, a creative agency dedicated to transforming the way we perceive food everyday. After pursuing an M.Sc. in International Business and specialising in entrepreneurship, Jashan founded Food Design Nation. He is the founding editor of FDzeeN: Art, Culture, and Design for Sustainable Food Systems and has served as the food and space correspondent for The Dutch Institute of Food & Design and Director at the Online School of Food Design. Jashan regularly hosts 3D printing food tastings and demonstration sessions, develops 3D printed food concepts for clients, and speaks globally about this emerging technology.

P.S. – If you want to learn in-depth how 3D food printing works, and want to develop your own concept for a 3D printed product or experience, check out Jashan’s training program 3D Printing Food. You can witness the creation of your edible 3D printed prototype and use the photos and videos in your portfolio, research project, on social media or for your funding application. If you’re already working on a 3D food printing project, you can book a 1-1 session with Jashan to get feedback and collaborate.

Leave A Comment