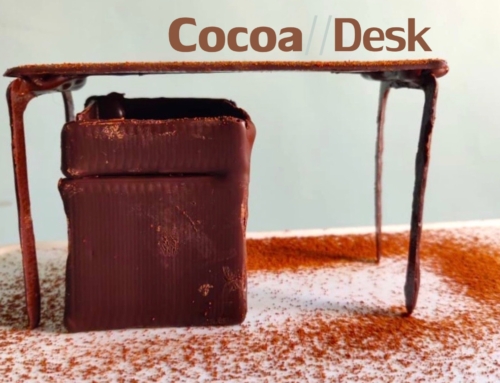

No, your eyes and brain are not deceiving you. Yes, you read that right – 3D printing. Food.

There are more advancements than ever before in this niche field – from food companies – big and small, to food services and edible packaging, and even in space exploration! We asked Jashan Sippy, a food-architect and 3D food printing expert to share his views.

3D food printing for healthcare

“Perhaps the main difference with respect to conventional meals is that the final presentation of 3D printed food is more complex, intricate, and geometric than the mushy lumps of puree counterparts. This can dramatically help increase the patients’ desire to ingest their required nutrients, and enable them to heal faster, and increase the patient turnover,” Jashan stated.

- Personalization: 3D printing opens the door to precision customization and therefore enables healthcare providers to respond to the individual needs of their patients. “You are in full control of flavour, and nutritional value including vitamins and minerals, sodium and sugar, and calories. The possibilities are endless, and always leave a smile on your customer’s faces – guaranteeing loyalty. What more could you want?”, Jashan commented.

- Wellbeing: 3D food printing offers you the opportunity for personalization. Jashan explains, “Serving patients nutritious food, with the textures they need, and presenting it to them in the form of their favourite food can help trigger positive, nostalgic memories and encourage them to ingest their daily requirements. This is a massive challenge that health providers face on a daily basis.”

Specific use cases of 3D printing food for healthcare

- For the elderly and dysphagic: A German company is using 3D food printing to create accessible meals for seniors who struggle to process solid foods. People who have health problems, for example, the elderly who have a mastication or chewing problems. These smooth foods that can be 3D printed there can be presented in appealing way to help increase appetite but also serve the functional aspect of being able to chew and swallow without choking.

- Jashan shares how the whole ecosystem of 3D printed smooth food works. “You have your set of consumers, let’s say, in your nursing home or hospital. Through a database of dietary restrictions, preferences. And updated nutritional requirements, we create specific personalized 3D food printed pastes at a production site. These can be frozen and dispatched too multiple centres, or printed on site and served fresh to the patients. The consumers preferences are updated, feedback is collected and it’s a loop that continues”.

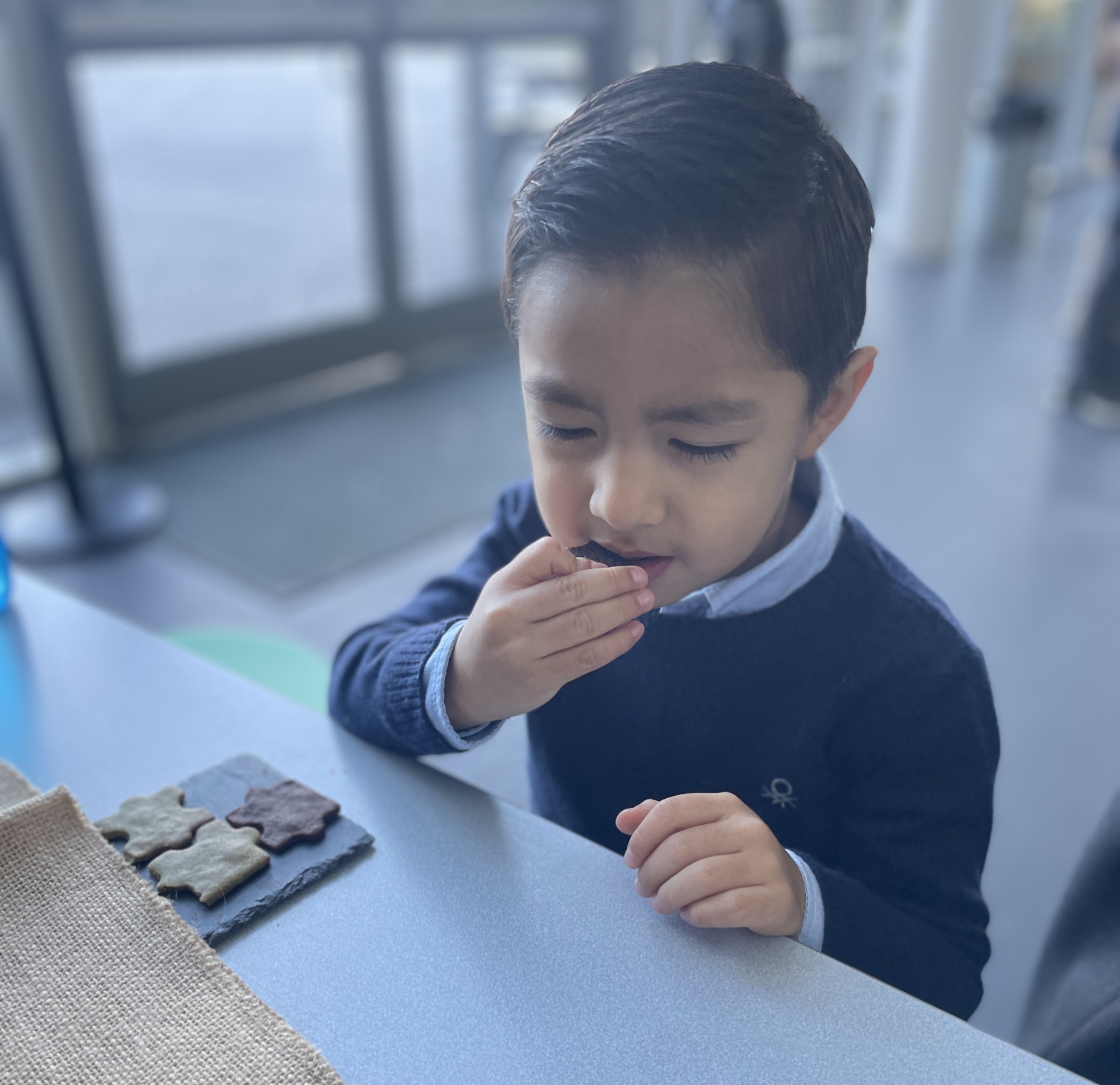

- For the young and neophobic: Research shows that food preferences develop as early as in the womb, later on flavours pass through breast milk, and for a determined period of time one likes what our mothers have eaten. In international and metropolitan cities like London, New York and Dubai, the vast majority of people come from different backgrounds, but their children do not develop a palate for ethnic foods – by sheer lack of exposure.

- Jashan added, “I worked on a projet to develop 3D printed edible toys using ingredients that can be adjusted to serve ethnic toddlers in these cities from Asia or Africa, etc. The aim is to expose children to new flavours at an early age by reconnecting them to their mother’s roots, reconnecting them to those indigenous ingredients their mothers and ancestors ate. The prototypes created with Betty Artuc use nutritious superfoods from Latin America like lupin, cassava, amaranth and alfalfa, but this is not limited to one geographical location.”

Are you or someone you know working with 3D food printing? How do you think 3D food printing can benefit your product or service?

About Jashan Sippy:

Jashan is a green-building certified architect specialised in the design for spaces for food. He is the founder of Sugar and Space, a creative agency dedicated to transforming the way we perceive food everyday. After pursuing an M.Sc. in International Business and specialising in entrepreneurship, Jashan founded Food Design Nation. He is the founding editor of FDzeeN: Art, Culture, and Design for Sustainable Food Systems and has served as the food and space correspondent for The Dutch Institute of Food & Design and Director at the Online School of Food Design. Jashan regularly hosts 3D printing food tastings and demonstration sessions, develops 3D printed food concepts for clients, and speaks globally about this emerging technology.

P.S. – If you want to learn in-depth how 3D food printing works, and want to develop your own concept for a 3D printed product or experience, check out Jashan’s training program 3D Printing Food. You can witness the creation of your edible 3D printed prototype and use the photos and videos in your portfolio, research project, on social media or for your funding application. If you’re already working on a 3D food printing project, you can book a 1-1 session with Jashan to get feedback and collaborate.

Leave A Comment