While there are more advancements than ever before in this niche field – from food companies and patisseries, to healthcare and even in space exploration – 3D printing food does have its fair share of drawbacks. We asked Jashan Sippy, a food-architect and 3D food printing expert to share his experience working with 3D printing food and its associated challenges. Excerpts from our conversation below.

Challenges associated with 3D printing food

- Capacity: Within the parameters of 3D food printing, capacity is a major limiting factor. “You’re usually limited to the volume of one particular cartridge. So how big your 3D printed element (portion size) can be depends on the volume of your cartridge,” Jashan pointed out.

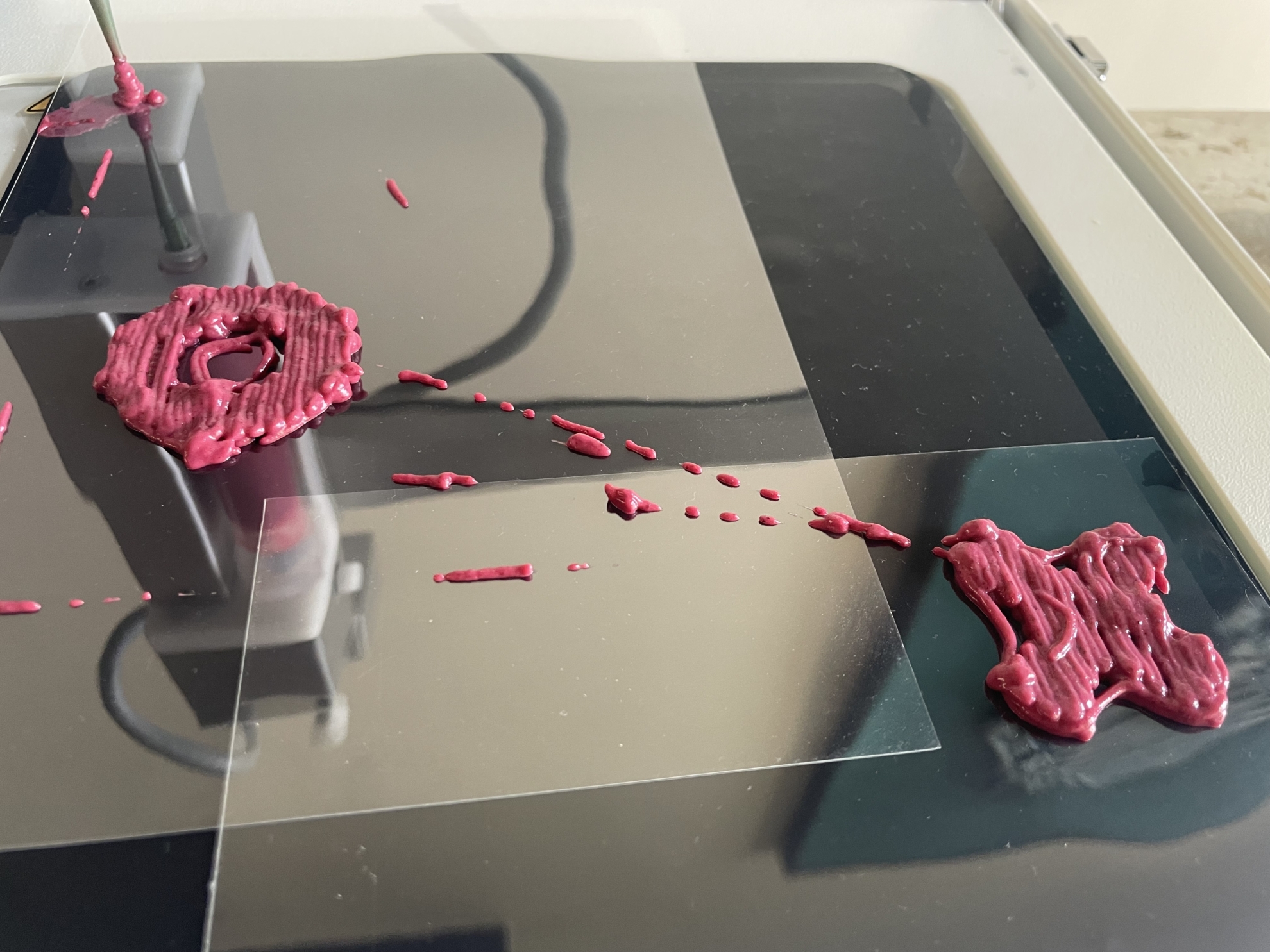

- Material inflexibility: For extrusion 3D printers, pretty much anything that can be pureed can be printed. Yes, that is a wide range of ingredients, but the consistency is a limited factor. “Only ingredients that can be pureed into a very homogenous smooth paste can make their way through the nozzle,” Jashan explained. “Furthermore, the edibles used in the machine require either pre-cooking or pre-processing to achieve the consistency required for extrusion. Therefore, the expected reproducibility and reliability of these machines depends heavily on proper preparation of those materials, subject to human error.”

- Compatibility: While most printers can be connected to Wi-Fi, there is still a lot to be done in terms of in-built software, including the possibility to plugin external 3D modelling tools and other devices. Jashan pointed out, “At the end of the day, this is something that is being constantly developed in order to make the life of a 3D food printing technician more comfortable. 3D food printing is just about 20 years old. The advancements will come much quicker upon widespread adoption. It’s just a matter of time”.

- Lack of industry standards: You have to be prepared to run into unforeseen challenges and to modify your processes and adapt your operations systems depending on which market(s) you’re working in, in order meet all the compliance and legal requirements. “Depending on where you are, this could be a good thing, or a bad thing in terms of ease of operations for your 3D food printing business,” noted Jashan.

- Cost: The printers themselves are capital-intensive and there’s also costs associated with training the right staff in order to get appropriate results. :The cost of the consumables also present barriers, especially if you need to purchase the input material from the supplier as well – in the long run, this can work out to be quite expensive. So choose wisely,” Jashan warns.

- Acceptance: While there is an aspect of fascination within a certain section of the market, there’s also hesitation within more traditional markets. Jashan said, “When you tell people that you work with 3D printed food, it takes some time for them to understand the process and perceive what 3D printed food might be. They’re usually quite sceptical about what is being printed, what is the outcome, and are sometimes hesitant to try ‘synthetic/unnatural printed food’. People take time to accept that this is real food or this can be healthy food or this can be good, tasty, and real food.”

- Time: Although times can vary based on the printer and the food being printed, it can range anywhere between 7 to 45 minutes based on the complexity of the model. “While this might not seem like too much at first glance, when you want to run this on a daily basis, and if your whole business depends on operating the printer, then the slow speed can start posing various challenges. You will probably need more than one printer in order to produce more, and faster,” Jashan stated.

- Scalability: As it is as of today, 3D food printing lacks scalability. “I’ve tried to use this in different events and we’re restricted by the capacity, the number of people, what kinds of foods we can take to the events, etc.”, Jashan expressed.

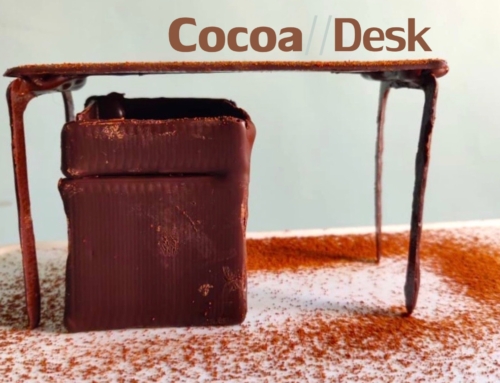

3D printed food is still in its infancy, and it has a really long way to go before we can start seeing it being broadly adopted by professionals as well as consumers. However this doesn’t stop us from marvelling at all the fascinating machines and the intriguing edible designs that are possible to create using this emerging technology.

About Jashan Sippy:

Jashan is a green-building certified architect specialised in the design for spaces for food. He is the founder of Sugar and Space, a creative agency dedicated to transforming the way we perceive food everyday. After pursuing an M.Sc. in International Business and specialising in entrepreneurship, Jashan founded Food Design Nation. He is the founding editor of FDzeeN: Art, Culture, and Design for Sustainable Food Systems and has served as the food and space correspondent for The Dutch Institute of Food & Design and Director at the Online School of Food Design. Jashan regularly hosts 3D printing food tastings and demonstration sessions, develops 3D printed food concepts for clients, and speaks globally about this emerging technology.

P.S. – If you want to learn in-depth how 3D food printing works, and want to develop your own concept for a 3D printed product or experience, check out Jashan’s training program 3D Printing Food. You can witness the creation of your edible 3D printed prototype and use the photos and videos in your portfolio, research project, on social media or for your funding application. If you’re already working on a 3D food printing project, you can book a 1-1 session with Jashan to get feedback and collaborate.

Leave A Comment